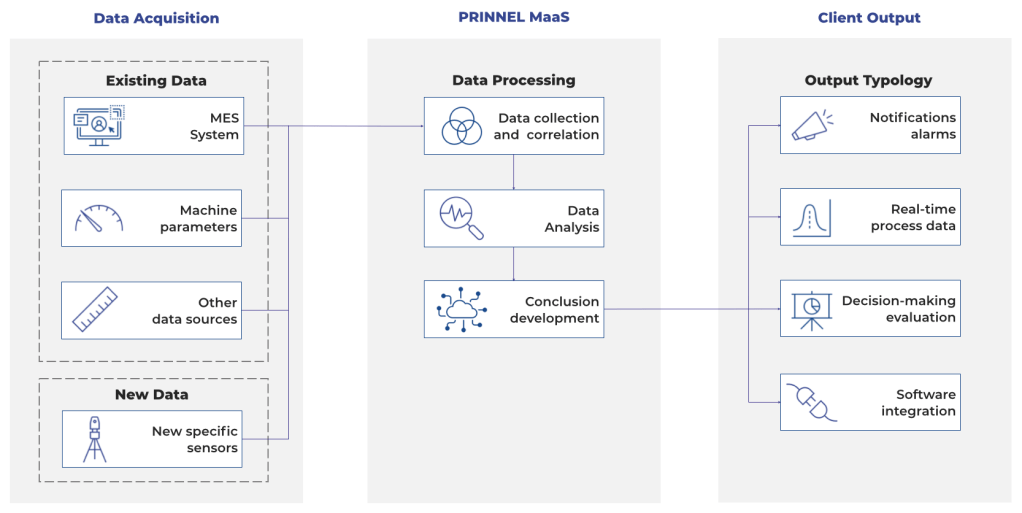

We specialise in the management and monitoring of industrial infrastructures for real-time acquisition of process and electromechanical performance data using existing or specially implemented sensors.

We collect and analyse industrial data through existing sensors or new devices and infrastructures to develop actionable conclusions, presenting the results in various formats, times, systems and interfaces.

Data Acquisition

We deploy specialised sensors to capture detailed data on key operational parameters such as temperature, pressure, vibration, and flow rates, among others. These sensors are carefully tailored to the machinery’s specific design and operational context, ensuring both high accuracy and relevance of the collected data. Operating in real time, they provide continuous monitoring of equipment conditions, enabling early detection of anomalies and deviations from optimal performance. This data is essential for effective performance tracking, predictive maintenance planning, and process optimisation. Ultimately, this approach enhances operational efficiency, minimises unplanned downtime, and contributes significantly to cost reduction and increased productivity.

Data Analytics

Through advanced data analysis techniques—such as signal processing, trend analysis and machine learning—the collected data is transformed into actionable insights. These methods enable early detection of inefficiencies, such as energy overconsumption or mechanical imbalances, and provide predictive indicators of potential component failures, allowing maintenance to be scheduled proactively rather than reactively. Additionally, real-time optimisation of cycle times is achieved by dynamically adjusting machine parameters based on current operating conditions. Together, these capabilities lead to significantly improved machine utilisation, minimised unplanned downtime, and a substantial boost in overall productivity across the manufacturing process.